Sunday, July 06, 2008

Monday, December 24, 2007

Systemic Sustainability - Master of Architecture Thesis

Large version: size 12 font, 1.5 line spacing, 126 pages, single-sided.

http://sckchui.googlepages.com/sckchui_Thesis_2007.pdf

Small version: size 8 font, single line spacing, 41 pages, double-sided

http://sckchui.googlepages.com/sckchui_Thesis_2007_small.pdf

Systemic sustainability:

concepts and strategies for overcoming resource depletion and environmental degradation

Abstract

This thesis seeks to understand and find solutions to two of the most pressing problems in the contemporary world, resource depletion and environmental degradation, both of which are results of the massive and pervasive industrialisation of human activity. The thesis begins with a discussion of the successes and flaws of industrialism. Industrialism is a phenomenon that inherently optimises labour productivity and neglects future environmental constraints until they are unavoidably apparent. The result is that industrialism has simultaneously dramatically improved human prosperity and caused dramatic environmental damage. This thesis briefly summarises four fields of sustainability study that have emerged to address the shortcomings of industrialism, looking for ways to eliminate its propensity for environmental damage while retaining its ability to provide prosperity to humanity. The four fields are environmental economics, industrial ecology, sustainable urbanism and lean management, covering many facets of the phenomenon of industrialism and a diversity of concerns. A close look at the four fields reveals some commonalities in their assumptions and strategies, in particular: the need to maintain a whole-system perspective to avoid dysfunctional isolation that comes with the uncritical application of the division of labour; the use of networked modularity as an organisational principle to overcome rigid and unresponsive management hierarchies and to give systems the flexibility to change and adapt, and; the application of pervasive knowledge enabled by information technologies to better control processes and capture system externalities. These commonalities challenge the fundamental assumptions underlying industrialism, pointing towards a culture of systemic sustainability that will replace the existing culture of systemic consumerism. Finally, this thesis briefly discusses some outcomes that can be expected, should the ideas in this thesis be applied. As a whole, this thesis seeks to contribute to humanity’s transition from the current self-destructive form of industrialism to a form that is sustainable and viable in the long term.

Monday, November 12, 2007

Thesis draft, as of 12/11/2007

http://sckchui.googlepages.com/sckchui_Thesis_Draft_e_001.pdf

[edit 14/11/2007] Ok I've started proof reading the draft. There are multiple mistakes/changes to be made on every single page, so be warned if you're reading the draft. It's a draft.

[edit 21/11/2007] More recent draft here. Very close to the final work, if this is not it already.

http://sckchui.googlepages.com/Thesis_Draft_e_006.pdf

[edit 24/12/2007] See the final thesis instead.

Emerging themes in sustainability and the need for applied systems solutions

Emerging themes in sustainability and the need for applied systems solutions

30 August 2007

Author:

Simon Chun Kwan Chui,

Master of Architecture student at The University of Auckland, New Zealand

sckchui@gmail.com

Based on research for a Master of Architecture degree supervised by Dr. Ross Jenner of The University of Auckland

Abstract

The world since the industrial revolution has seen improvements to human welfare on a massive scale, but also environmental problems on a massive scale. A summary of the emerging sustainability fields of environmental economics, industrial ecology, sustainable urbanism and lean management reveals a call for a sophisticated whole-system perspective in tackling these problems, emphasising decentralised and streamlined relationships between system elements. Taken as a whole, these initiatives indicate a cross-discipline paradigm-shift towards the application of systems theory as practical solutions to the shortcomings of industrialism, and suggest directions where future developments in systems theory and thinking will be most useful.

Conference themes

Organisational systems; Systems theory/systems thinking.

Keywords

Sustainability; resource depletion; environmental degradation; environmental economics; industrial ecology; sustainable urbanism; lean production; lean management; whole-system perspective; modularity; pervasive knowledge.

Introduction

Two of the most pressing problems in the contemporary world are resource depletion and environmental degradation, both results of the massive and pervasive industrialisation of human activity. While industrialism has provided tremendous improvements to human welfare over the past two and a half centuries, it also inherently neglects to factor in environmental constraints until substantial damage is done. This paper briefly summarises four fields that have emerged to address the shortcomings of industrialism, namely environmental economics, industrial ecology, sustainable urbanism, and lean management. This reveals some commonalities that suggest that a pervasive culture of sustainability, in contrast to the existing culture of consumerism, may be reached through the widespread application of systems theory to all facets of human endeavour. This paper identifies some specific issues where the application of systems theory will greatly benefit the continued development of the four fields.

The global industrial system

Industrialisation is a series of mutually supporting technological innovations developed some 250 years ago that changed human activity from predominantly agrarian to predominantly industrial (Grübler 1994). Practically synonymous with human activity, industry mobilises hundreds of billions of metric tonnes of raw materials every year (Hawken, et al. 1999: 50-53), extracting and transporting raw materials across the globe to sprawling factories and industrial zones to be transformed into the myriad consumer goods that are distributed to the cities and homes of the world’s consumer population (Graedel, et al. 1995: 8). In our industrial world, socio-economic success flows from technology applied to material production to maximise labour productivity (Kam 2001: 35-68, Swamidass 2000: 4).

Mass production and the division of labour

From the beginning of the industrial revolution over 200 years ago, the hierarchical subdivision of labour was identified as the basis of successful industrialism, utilising specialisation to enable improved worker skill and focus, and, most importantly, the utilisation of specialist tools and machines (Smith 1979: 110-115, Womack, et al. 1991: 12-13). Since 1750, human industrial output has grown by a about factor of 100, the outcome of the increasing utilisation of sophisticated mechanical tools to multiply labour productivity (Grübler 1994: 41). By all measures, overall human welfare has been improved by industrialisation: people live longer; infant mortality is reduced; food supply per capita is greater and more stable; people work fewer hours while output has increased; education levels have improved; and people are more likely enjoy the benefits of living in a democratic and pluralistic society (Goklany 2003: 195-198).

Resource depletion and environmental degradation

Despite the benefits of industrialism, there have also been substantial costs. Industrialism, by definition, is a process that transforms natural resources into human-made artefacts (Bourg 2003: 59), and the success of industrialism came hand in hand with the large scale depletion of natural resources and damage to the environment (Hawken, et al. 1999: 2). Of the hundreds of billions of metric tonnes of raw materials mobilised every year, some 90 percent are immediately discarded as they are not the resources that are actually desired, but only material that is disrupted by the processes of extraction (Graedel, et al. 1995: 19). Less than 2 percent of the material is actively recycled at the end of their use (Hawken, et al. 1999: 50-53), and only 1 percent remains in use within the system six months after its extraction (Dale 2006: 4). In other words, the industrial system is one where materials flow rapidly from un-extracted resource to discarded waste, in processes that involve substantial environmental disruption.

Four responses to environmental limits

In the past, the response to localised resource depletion has simply been to find more resources or to find substitutes (Bourg 2003: 58, Graedel, et al. 1995: 66), while the response to local environmental degradation has been to capture and control effluents and to remediate any damage done (Bringezu 2003: 21, Graedel, et al. 1995: 47). As both industrial activity and environmental constraints become increasingly global in scope, these responses become inadequate. The four developing fields summarised below take a different approach: they seek to address some fundamental shortcomings in traditional industrialism.

Environmental economics

Economics is the codification and quantification of human needs and wants, and the activities we conduct in order to satisfy them (Graedel, et al. 1995: 63-64). A primary shortcoming of current economic systems is the presence of “externalities”: activities that have real costs and benefits, but which are not entirely factored into prices, and therefore not fully accounted for in decision-making mechanisms (Graedel, et al. 1995: 86). The aim of environmental economics is to adjust market incentive/disincentive mechanisms so that as many externalities as possible are internalised, and that these enter decision-making processes early enough to significantly influence outcomes. Possible initiatives include waste taxes and recycling subsidies that reflect the true costs and benefits of these activities to society (Graedel, et al. 1995: 82, Griefahn 1994: 424-425, Hawken, et al. 1999: 41-42, 159-167), and the realignment of prices so that they focus on services provided, rather than on products sold, thereby removing the market’s emphasis on material throughput (Graedel, et al. 1995: 305, Hawken, et al. 1999: 10-11, Kazazian 2003: 85-86, Stahel 2003: 266). By adjusting the rules of the system, environmental economics hopes to address a dysfunction that pervades all aspects of the system at every scale.

Industrial ecology

Industrial ecology looks to natural ecological systems as a model for redesigning human industrial systems (Bringezu 2003: 20, Hawken, et al. 1999: 10). In contrast to the resource depleting model of human industrialism, material flows in natural ecosystems are overwhelmingly cyclic: the outputs of any one organism become inputs for other organisms, and the volume of material cycling within the system are much greater than the volume entering or leaving it. If human industry can successfully mimic this cyclic paradigm, then the problems of resource depletion and environmental degradation can be largely eliminated (Bringezu 2003: 22, Dale 2006: 3, Graedel 1994: 23-26, Graedel, et al. 1995: 93-94). The primary challenges of industrial ecology are the re-conceptualisation of “wastes” as “resources”, the development of process technologies that retain the embedded utility of residues from industrial processes (Graedel, et al. 1995: 113, 183-186), and the development of markets for the exchange and redeployment of these residual resources (Braungart 1994: 335-336, Graedel, et al. 1995: 83, Kincaid 2003: 97-99, Yap 2006: 101). From the perspective of industrial ecology, the industrial system is incomplete in its current configuration, so existing resource distribution mechanisms need to be extended and augmented to include residual products.

Sustainable urbanism

After Second World War, urbanism in the West has been characterised by substantial amounts of sprawl: low-density development that, while attractive and in demand in the market, require high infrastructure costs, consumes large amounts of land, and necessitates expensive private automobile use (Burchell, et al. 1998: 1-26, Grant 2006: 50-53). This unsustainable, consumerist approach to urbanism been met by initiatives like New Urbanism and Smart Growth that, among other things, advocate for geographical limits on urban development to preserve agricultural lands and natural habitats (Yaro 1999: 23-25), better integration and coordination of civic governance to prevent conflicting priorities in civic management (Orfield 1999: 65-69), and the creation of concentrated and mixed use neighbourhood centres to improve urban vitality (Barnett 1999: 73-77, Norquist 1999: 97-99, Plater-Zyberk 1999: 79-82). Most significantly, sustainable urbanism recognises that complex and highly interconnected urban influences require holistic solutions, and that attempting to address specific urban problems in a piecemeal manner will only aggravate system dysfunction.

Lean management

Under conventional management hierarchies, the increasing complexity of the subdivision of labour results in highly inflexible and unresponsive production systems. In aversion to costly stoppages, non-critical defects and mistakes are simply allowed to continue and be passed down the line to be remedied later. Processes are seldom changed or improved due to the high costs, resulting in unnecessary waste (Womack, et al. 1991: 12-14, 24-26). Lean production overcomes these shortcomings through pervasive modularisation, dividing the production line into discreet process stages that are linked together with streamlined communication and inventory management mechanisms. Each stage of the work is then associated with a work cell, a small and semi-autonomous team of multi-skilled workers. Responsiveness is improved by allowing routine decision-making to be done at a lower management level, and flexibility is increased as cells can be added to or removed from the system without disruption to the larger system. This reduces, with the aim of eliminating, the unnecessary and non-value-adding consumption of resources (Black 2000: 177-178, Feld 2001: 3-6, McCreery and Bloom 2000: 97-101, Womack, et al. 1991: 49-68).

Common strategies for systemic sustainability

On the surface, the four fields vary widely in scope and in focus. However, there are significant commonalities in the different approaches to addressing the shortcomings of contemporary industrialism. These commonalities, summarised below, indicate that the solution will involve the widespread practical application of systems theory. Although the concerns are conceptually separated into three major themes here, it should be noted that they are mutually supportive, and unlikely to be useful if each is considered and implemented in isolation.

Whole-system perspective

The most frequently expressed concern is the need for a whole-system perspective in process design and implementation (Fischer-Kowalski 2003: 44-45, Hawken, et al. 1999: 64, Hodge 2006: 159, Kazazian 2003: 85, Stahel 2003: 267-268). While the division of labour creates highly proficient specialisations, it does not guarantee that they will come together into a complete system. This is evident in a market system that neglects and inadvertently promotes resource depletion and environmental damage on a massive scale, in industrial systems that neglect the residues they produce (Graedel, et al. 1995: 8), and in a piecemeal approach to urban design that neglects the interdependency of social, economic, and infrastructural issues. In all cases, the benefits of specialisation need to be complemented by a whole-system perspective that creates an understanding of the relationship between each specialist and the whole system, allowing the active building of useful connections between entities in order to capture potential synergies and prevent dysfunctional system behaviour (Côté and Wallner 2006: 130, Dale 2006: 10, Gibson and Peck 2006: 137-138, Stahel 2003: 273). Obviously it would be counterproductive if increased connections between entities simply resulted in excessive complexity and information overload. Therefore, the challenge is to devise mechanisms to transfer and internalise only the useful types and amounts of information, and to devise mechanisms that can quickly detect and highlight the presence of externalities so that they can be acted upon.

Modular networks

A second major theme is the use of modularity as a means to achieve systemic flexibility and upgradability where modules can be added, subtracted, or modified with minimal system disruption (Duray 2000: 280-281, Stahel 2003: 272). The need is for modular systems where each module has the sufficient mix of resources to perform its function while remaining small enough to be agile and responsive (Graedel, et al. 1995: 328-332, Stahel 2003: 273-274). System-wide coordination is achieved through unobtrusive yet pervasive and powerful incentive/disincentive mechanisms that can translate overarching goals into specific actions to be performed in each module of management (Andrews 1994: 406-410, 412-415, Gibson and Peck 2006: 141-144, Graedel, et al. 1995: 80-82 293-295, Griefahn 1994: 424-425, Hawken, et al. 1999: 41-42, 90-93, 159-167, Panayotou and Zinnes 1994: 389-391, Stahel 2003: 271, Yap 2006: 105-107). This modularity retains the advantages of the specialisation and the division of labour while employing more flexible and streamlined connections between process segments that facilitate effective transfer of materials and knowledge, avoiding specialisation isolation. Minor disruptions are autonomously handled within modules, and are prevented from spilling out beyond individual modules to affect the larger system. The deployment and management of modules may be substantially automated by the careful design of rules and guidelines that determine optimum module size and composition in relation to the system, and the design of the mechanisms of exchanges between modules such that they network into a successful system.

Pervasive knowledge

Any system that is as complex and dynamic as cities or large industrial systems will exhibit unpredictable behaviour and non-linear interactions between elements (Bourg and Erkman 2003: 14, Gibson and Peck 2006: 139-140, Hawken, et al. 1999: 113-121, Hodge 2006: 159). In such a complex system, detailed centralised planning is impractical as it necessitates the collection and analysis of vast amounts continuously changing data in an attempt to monitor dynamic and multi-faceted situations (Lister 2006: 18-21). An alternative strategy is to incorporate into each system element effective feedback and feed-forward mechanisms that are designed to allow them to automatically optimise themselves in shifting conditions, which, in turn, allows the system to find its own “plan” (Hawken, et al. 1999: 127-131). Such a system would require a sophisticated and pervasive knowledge infrastructure to continuously collect accurate and useful information when and where it is generated, to be distributed to wherever feedback action is required (Hill 2006: 44-46). The point of pervasive knowledge is to avoid flooding a centralised decision-making mechanism with excessive data and to direct information effectively to wherever it will be useful, with minimum or no input necessary from a centralised decision-making mechanism. An essential aspect of pervasive knowledge is the translation of raw data from any one system element into information that will be useful and applicable to other system elements, or, in other words, the development of an effective knowledge infrastructure. The “pervasive” aspect of pervasive knowledge highlights the need for knowledge to be collected and be made applicable at all levels and in all situation; the knowledge infrastructure itself, like all the system elements that it serves, should have mechanisms that constantly collects and processes feedback information to ensure that it is functioning effectively.

Conclusion

Sustainability, in addressing the problems of resource depletion and environmental degradation in human industrialism, has identified the problem as an inability to sufficiently understand the complex interrelationships between all aspects of natural and human activity, and an inability to effectively coordinate the complexity of increasing specialisation. It is not surprising that the four fields summarised in this paper, in dealing with the problem of sustainability, all begin to look to concepts from systems theory for solutions to dealing with complexity across issues that vary so widely in scope and in focus. The significance is that these four fields do not simply propose to “patch up” industrialism’s negative symptoms with localised fixes; these are paradigm-shifting proposals that aim to reengineer the entire industrial system by reassessing its basic strategies and underlying assumptions. If these initiatives, and others like them, eventually come to affect every aspect and scale of human activity, just as industrialism has done in the past centuries, then it may be that the practical application of systems theory will also become as routine and commonplace as the tools of industrialism are today. Tools that will need to be developed will likely include: automated mechanisms for the collection, processing, and distribution of useful information at local and global scales; techniques for quickly detecting and highlighting the existence of externalities; a framework for assembling multi-skilled, self-managed teams as a module of a larger system, and; protocols and infrastructure for the streamlined transfer of information, materials and incentives between system elements.

References

Andrews, C. (1994). "Policies to Encourage Clean Technology," in R. H. Socolow, C. Andrews, F. Berkhout and V. Thomas (ed.), Industrial ecology and global change, ISBN 0521471974, pp. 405-422

Barnett, J. (1999). "Ten; The neighborhood, the district, and the corridor are the essential elements of development and redevelopment in the metropolis. The form identifiable areas that encourage citizens to take responsibility for their maintenance and evolution," in M. Leccese, K. McCormick and Congress for the New Urbanism (ed.), The charter of the new urbanism, ISBN 0071355537, pp. 73-77

Black, J. T. (2000). "Lean Manufacturing Implementation," in P. M. Swamidass (ed.), Innovations in competitive manufacturing, ISBN 0792378962, pp. 177-186

Bourg, D. (2003). "Industrial Ecology; Philosophical and Political Meanings," in D. Bourg and S. Erkman (ed.), Perspectives on industrial ecology, ISBN 1874719462, pp. 58-61

Bourg, D. and Erkman, S. (ed.). (2003). Perspectives on industrial ecology, ISBN 1874719462.

Braungart, M. (1994). "Product Life-Cycle Management to Replace Waste Management," in R. H. Socolow, C. Andrews, F. Berkhout and V. Thomas (ed.), Industrial ecology and global change, ISBN 0521471974, pp. 335-337

Bringezu, S. (2003). "Industrial Ecology and Material Flow Analysis; Basic Concepts, Policy Relevance and Some Case Studies," in D. Bourg and S. Erkman (ed.), Perspectives on industrial ecology, ISBN 1874719462, pp. 20-34

Burchell, R. W., United States. Federal Transit Administration., National Research Council (U.S.). Transportation Research Board., Transit Development Corporation. and Transit Cooperative Research Program. (1998). The Costs of sprawl-- revisited, ISBN 030906306X.

Côté, R. P. and Wallner, H. P. (2006). "From Clusters and Networks to Islands of Sustainability," in R. P. Côté, J. Tansey and A. Dale (ed.), Linking industry and ecology : a question of design, ISBN 9780774812139, pp. 114-133

Dale, A. (2006). "Linking Industry and Ecology in Canada: A Question of Design," in R. P. Côté, J. Tansey and A. Dale (ed.), Linking industry and ecology : a question of design, ISBN 9780774812139, pp. 3-11

Duray, R. (2000). "Mass Customization," in P. M. Swamidass (ed.), Innovations in competitive manufacturing, ISBN 0792378962, pp. 275-282

Feld, W. M. (2001). Lean manufacturing : tools, techniques, and how to use them, ISBN 157444297X.

Fischer-Kowalski, M. (2003). "On the History of Industrial Metabolism," in D. Bourg and S. Erkman (ed.), Perspectives on industrial ecology, ISBN 1874719462, pp. 35-45

Gibson, R. B. and Peck, S. W. (2006). "From Advanced Eco-Efficiency to Systemic Sustainability: What Leading Companies are Doing and What Assistance and Pressure They Need from Governments and Other Players," in R. P. Côté, J. Tansey and A. Dale (ed.), Linking industry and ecology : a question of design, ISBN 0774812133, pp. 134-150

Goklany, I. M. (2003). "The Future of the Industrial System," in D. Bourg and S. Erkman (ed.), Perspectives on industrial ecology, ISBN 1874719462, pp. 194-222

Graedel, T. E. (1994). "Industrial Ecology: Definition and Implementation," in R. H. Socolow, C. Andrews, F. Berkhout and V. Thomas (ed.), Industrial ecology and global change, ISBN 0521471974, pp. 23-41

Graedel, T. E., Allenby, B. R. and American Telephone and Telrgraph Company. (1995). Industrial ecology, ISBN 9780131252387.

Grant, J. (2006). "Industry in the City: From Industrial Ghettos to Eco-Parks," in R. P. Côté, J. Tansey and A. Dale (ed.), Linking industry and ecology : a question of design, ISBN 9780774812139, pp. 50-66

Griefahn, M. (1994). "Initiatives in Lower Saxony to Link Ecology to Economy," in R. H. Socolow, C. Andrews, F. Berkhout and V. Thomas (ed.), Industrial ecology and global change, ISBN 0521471974, pp. 423-428

Grübler, A. (1994). "Industrialization as a Historical Phenomenon," in R. H. Socolow, C. Andrews, F. Berkhout and V. Thomas (ed.), Industrial ecology and global change, ISBN 0521471974, pp. 43-68

Hawken, P., Lovins, A. B. and Lovins, L. H. (1999). Natural capitalism : creating the next industrial revolution, ISBN 0316353167.

Hill, S. B. (2006). "Redesign as Deep Industrial Ecology: Lessons from Ecological Agriculture and Social Ecology," in R. P. Côté, J. Tansey and A. Dale (ed.), Linking industry and ecology : a question of design, ISBN 9780774812139, pp. 29-49

Hodge, R. A. (2006). "Mining, Minerals, and Sustainability," in R. P. Côté, J. Tansey and A. Dale (ed.), Linking industry and ecology : a question of design, ISBN 9780774812139, pp. 151-175

Kam, W. P. (2001). "From Leveraging Multinational Corporations to Fostering Technopreneurship: The Changing Role of S&T Policy in Singapore," in L. Low and D. M. Johnston (ed.), Singapore Inc. : public policy options in the third millennium, ISBN 9812101594, pp. 35-84

Kazazian, T. (2003). "The Ecodesign Process," in D. Bourg and S. Erkman (ed.), Perspectives on industrial ecology, ISBN 1874719462, pp. 82-90

Kincaid, J. (2003). "Metropolitan Industrial Ecosystem Development," in D. Bourg and S. Erkman (ed.), Perspectives on industrial ecology, ISBN 1874719462, pp. 95-100

Lister, N.-M. (2006). "Industrial Ecology as Ecological Design: Opportunities for Re(dis)covery," in R. P. Côté, J. Tansey and A. Dale (ed.), Linking industry and ecology : a question of design, ISBN 9780774812139, pp. 15-28

McCreery, J. K. and Bloom, M. C. (2000). "Teams: Design and Implementation," in P. M. Swamidass (ed.), Innovations in competitive manufacturing, ISBN 0792378962, pp. 95-106

Norquist, J. O. (1999). "Fourteen; Transit corridors, when properly planned and coordinated, can help organize metropolitan structure and revitalize urban centers. In contrast, highway corridors should not displace investment from existing centers," in M. Leccese, K. McCormick and Congress for the New Urbanism (ed.), The charter of the new urbanism, ISBN 0071355537, pp. 97-99

Orfield, M. (1999). "Nine; Revenues and resources can be shared more cooperatively among the municipalities and centers within regions to avoid destructive competition for tax base and to promote rational coordination of transportation, recreation, public services, housing, and community institutions," in M. Leccese, K. McCormick and Congress for the New Urbanism (ed.), The charter of the new urbanism, ISBN 0071355537, pp. 65-69

Panayotou, T. and Zinnes, C. (1994). "Free-Lunch Economics for Industrial Ecologists," in R. H. Socolow, C. Andrews, F. Berkhout and V. Thomas (ed.), Industrial ecology and global change, ISBN 0521471974, pp. 383-397

Plater-Zyberk, E. (1999). "Eleven; Neighborhoods should be compact, pedestrian-friendly, and mixed-use. Districts generally emphasize a special single use, and should follow the principles of neighborhood design when possible. Corridors are regional connectors of neighborhoods and districts; they range from boulevards and rail lines to rivers and parkways," in M. Leccese, K. McCormick and Congress for the New Urbanism (ed.), The charter of the new urbanism, ISBN 0071355537, pp. 79-82

Smith, A. (1979). The wealth of nations : books I-III, ISBN 0140432086.

Stahel, W. R. (2003). "The Functional Society; the Service Economy," in D. Bourg and S. Erkman (ed.), Perspectives on industrial ecology, ISBN 1874719462, pp. 264-282

Swamidass, P. M. (2000). "Innovations in competitive manufacturing: From JIT to e-business," in P. M. Swamidass (ed.), Innovations in competitive manufacturing, ISBN 0792378962, pp. 3-14

Womack, J. P., Jones, D. T. and Roos, D. (1991). The machine that changed the world, ISBN 0060974176.

Yap, N. T. (2006). "Cleaner Production and Eco-Efficiency: Charting a Course for Sustainability," in R. P. Côté, J. Tansey and A. Dale (ed.), Linking industry and ecology : a question of design, ISBN 9780774812139, pp. 97-113

Yaro, R. D. (1999). "Two; Metropolitan regions are finite places with geographic boundaries derived from topography, coastlines, farmlands, regional parks, and river basins. The metropolis is made of multiple centers that are cities, towns, and villages, each with its own identifiable center and edges" in M. Leccese, K. McCormick and Congress for the New Urbanism (ed.), The charter of the new urbanism, ISBN 0071355537, pp. 23-25

ANZSYS 07 conference

The conference propaganda looks something like this:

Australia New Zealand Systems Conference 2007

“Systemic development: local solutions in a global environment”

2nd – 5th December 2007, Auckland, New Zealand

I'll post my conference paper as a separate post.

Monday, April 30, 2007

Masters Thesis Summary - Draft

The shape of a viable future – the necessary infrastructures for the sustainable development of human systems

As humanity heads into the twenty-first century, some unwelcome conclusions are becoming inescapable: the pattern of growth through consumption, the basis of human activity during the twentieth century, has become too successful for its own good, irreversibly depleting resources and negatively disrupting natural systems. What still escapes us is the way out of this predicament. What can we possibly do to halt and reverse this vehicle to self-destruction, without giving up the benefits and opportunities that our economy and technology allow?

In recent decades, several interrelated ideas have emerged and grown into substantial fields of study in order to address this concern from different angles: ecological economics; industrial ecology; new urbanism; and lean manufacturing. While each of these ideas has aspects that overlap the others, they largely operate at different scales and may work independently to address different parts of the problem. The aim of this thesis is to consider the common threads that may tie these ideas closer together into a comprehensive and systematic solution to the resource consumption problem, focusing on the synergies and catalytic effects each idea can have on the others.

Ecological economics seeks to modify the market system to factor in environmental (and possibly social) costs that, under the current system, are externalities. Externalities are those costs and benefits that a company may impose or provide, but which do not appear on the company’s balance sheets. An example may be the illegal logger, perhaps in Indonesia or South America, who cuts down virgin rainforest and sells the timber on the black market. For this logger, costs such as petrol for the chainsaw and income from selling the timber appear in his profit calculations. The costs of losing the services that the rainforest once provided, e.g. ecosystem support, habitat for wildlife, erosion control, climate regulation, carbon sink, etc., do not appear on any balance sheet anywhere, and yet they clearly represent a loss of natural capital to humanity as a whole. Alternatively, a person who plants a small forest is investing in natural capital, but he equally is not compensated financially for the services that his forest provides to humanity. Such externalities mean that the market leaves out certain very important items from its value system, leading economic activity in sometimes perverse and self-destructive directions. As far as such externalities can be internalised into the market system, preferably transferred to those parties that can most effectively deal with them, the market will begin to encourage constructive, instead of destructive, behaviour. Examples of ecological economic initiatives include the German packaging take-back law, which places the responsibility and costs of disposing of packaging back on the manufacturer, and the proposed carbon emissions trading schemes, which seeks to internalise the costs of carbon emissions into the finances of companies and countries. The former makes it more profitable to use as little packaging as necessary, while the latter aims to make it more profitable to limit carbon emission as much as possible, and both are incentives for more ecologically benign behaviour.

Industrial ecology combines the study of industrial metabolism with an ecosystem metaphor. Industrial metabolism studies the inputs and outputs of materials and energy in industrial processes as they strive to transform raw materials into useful products and services. Conventionally, industrial metabolism is conceived of as a linear flow, from extraction, to refining, to fabrication, to assembly, to consumption, to disposal. Natural ecosystems, on the other hand, are cyclic, from photosynthetic producers drawing nutrients from the ground and storing energy from the sun, to consumers who eat some of them, to decomposers who turn dead plants and animals and organic ‘wastes’ back into nutrients. In the natural ecosystem, both the input of previously bio-unavailable material into the system and the output of sequestered material out of the system are very small compared to the volume of nutrients cycling within the system. The goal of industrial ecology is to look for opportunities for industry to recycle and reuse residues and by-products as much as possible, and minimise the amount of material extracted from virgin sources and the amount of material dissipated or otherwise irrecoverably disposed of. To the extent that this is successful, the rate of resource depletion and environmental degradation due to industrial activity will be reduced, hopefully to levels that can be accommodated by natural systems. An example of a well-developed and formalised industrial ecosystem is in Kalundborg, Denmark, where a power station, a plasterboard company, a pharmaceutical plant, an enzyme producer, an oil refinery, and a waste company cooperate to utilise each other’s production by-products as input materials in complementary processes. Such symbiosis is both financially more profitable and environmentally more benign than if the companies operated separately.

New urbanism is concerned with the design of cities and, primarily, critical of suburban sprawl. In order for a city to function as a place of residence, commerce, community, and civilisation, city neighbourhoods need to be sufficiently dense and diverse with frequent interconnected streets and lanes and varied mixes of uses. In focusing on higher-density walk-able neighbourhoods that foster community and public vitality, new urbanism reduces the need for private automobiles and their associated pollution and fossil fuel consumption. Higher densities also mean closer distances between people and services, reducing the amount of roads and other necessary infrastructure, reducing the land area that is paved and built upon, thereby reducing the associated habitat destruction and environmental burden. Successful communities also become forces for decentralisation and democratisation; as higher density allow neighbourhood grocers, cafes, and other small shops to become economically viable, centralised supermarkets and shopping malls accessed by automobile, not exactly desirable to begin with, are no longer as necessary. Successful communities develop within themselves the social networks that enable economic cooperatives and political action. An oft cited example of a successful urban development that nurtures rather than destroys community is the city of Curitiba, Brazil, under the leadership of mayor Jaime Lerner, where zoning for density around an effective transportation network, the conversion of hydrologically sensitive areas to parks, and pragmatic social development initiatives were combined to make Curitiba one of the best examples of urban planning worldwide.

Lean manufacturing, ostensibly, is about the arrangement and the management of factory floor in a way that enables greater flexibility and whole-system productivity, while continuously seeking to eliminate waste of all kinds. The essence of lean manufacturing is the arrangement of labour into small, multi-skilled, semi-autonomous work teams which, when given the necessary tools and equipment, become semi-autonomous work cells. Each work cell is capable of and responsible for managing its own day-to-day activities, managing internal workload and workflow, routine maintenance of its equipment, and the monitoring and improvement of its performance. In this way, people with the most intimate knowledge of the situation at the shop floor do most of the routine decision-making. Each cell manages its own ‘suppliers’ and ‘customers’, whether these are other cells within the same company or entities from outside. Work is done on demand, in the form of a ‘pull’ signal from a customer, so that only work that is actually needed is done. Management is no longer given the task of making too many decisions with too little information. While the origin of lean manufacturing is the Toyota Production System, the possibilities for the application of lean principles extend far from the automobile factory. Compared with the semi-autonomous work team of the lean factory, the typical person simultaneously has too much and too little freedom. Too much freedom in that his activities need not respond to any real demand signal; too little freedom in that he does not have the authority or ability to optimise much of his ‘equipment’ (the streets, public utilities, the urban fabric, etc.). The decentralisation of civic authority to neighbourhoods and communities at all levels that have successfully acquired the skills and the tools to manage themselves may prove to be the key to more agile, more responsive, and less wasteful city management.

While each of the four themes can and do, to some extent, work independently towards addressing the problems of resource depletion and environmental degradation, they each have certain shortcomings that may prevent their full implementation. For example, ecological economics seeks to modify laws and market rules to internalise current externalities into companies’ finances, but where these represent significant short-term costs to the companies, they will be vigorously resisted. Industrial ecology seeks to make all of humanity’s material flows cyclic and non-dissipative, but where production and consumption are not on a large enough scales or sufficiently organised to make waste management economically viable, this cannot happen. New urbanism argues for compact city developments that make efficient use of infrastructure, but as long as cities are willing to subsidise roads and infrastructure for sprawling developments and as long as substantial automobile costs remain externalities, the automobile suburb will remain attractive. Lean manufacturing principles suggests the pervasive decentralisation of decision making authority to relatively small and localised groups of skilled and equipped individuals in order to increase the agility and efficiency of decision making, but these groups can only form within neighbourhoods with successful communities and they will not have anything to work on if current patterns of consumption remain the norm.

But here is where the mutually supporting nature of these four themes becomes apparent. Ecological economics would become much easier to implement if industrial ecology initiatives and new urban design have already made firms and cities more ecologically benign, and therefore have fewer costs imposed on them when integrating ecological accounting (perhaps they may even make a net profit from it, as both external costs and benefits are internalised). Industrial ecology can become economically viable for even the smallest of firms and households if they exist within a successful community where it is easy to pool resources and skills and to find niche opportunities. New urbanist city developments would become much more economically viable if ecological economics made it more evidently expensive to sprawl, and if people demanded functioning communities where they can profit through cooperation. Lean manufacturing style decentralisation and self-management can occur where new urbanist neighbourhood enables community action, and where ecological economics and industrial ecology initiatives require the organisation of cooperative action. This is the central proposition of this thesis: we already have the foundations of the solution to the great problem of our generation, resource depletion and environmental degradation, and we need only to implement all the partial solutions we have devised together as integrated system of mutually supporting elements.

It is difficult to foresee what the outcomes of this enterprise would be owing to the synergetic effects we hope, indeed we need, to create. Ideally, all present market externalities will become internalised: it will be very expensive to harvest natural resources, but even more profitable to regenerate natural capital; agriculture will be profitable if the soil has more nutrients in it at the end of the season than at the beginning; urban forms that displace local flora and fauna will be very expensive, but those that support and coexist with them will profit from it. The concept of ‘waste’ will become an anachronism: all individuals will automatically separate their residue streams to facilitate recycling or they will employ someone else to do it at a price; all residues will then be traded on a marketplace of residues, passing from those who want to be rid of it to those who can make use of it; products that are designed for recycling or, better yet, services provided without the transfer of products, will displace ‘consume and dispose’ as the self-evident economic logic. There will not be any part of any city that is dominated by a single use: residence, business, commerce, and clean industry will be located in close proximity to each other; circulation of people and materials will be local wherever possible, while knowledge and information will travel speedily around the globe; people will have the opportunity to come into contact with others in their neighbourhood without the mediation of the automobile, and the resulting community will profit from the social, economic, and political opportunities that this provides. Decentralised cooperative organisations will be given responsibility, authority and accountability for most of the services currently provided by centralised civic governments: neighbourhoods will plan their own land use and development rules, seamlessly taking into account the social and environmental concerns that have become internalised into their finances; neighbourhoods will organise the procurement of services and equipment that would be more economic to provide in as shared resources to the entire neighbourhood; neighbourhoods will internally process any refuse, wastewater, and sewage to the extent that it is economical to do so, and collectively arrange for the sale of any material that is better processed externally.

All these things will be the outcome of a human system that has successfully internalised the responsible custodianship of natural systems into its very core assumptions. This is the solution to the current socio-economic system that implicitly assumes the unlimited expansion of human consumption and counts the liquidation of natural assets as profit. While the distance that needs to be travelled seems great, the journey has already begun. The first steps have been taking by different people from different directions. By each enabling the opportunities of the others, they will arrive at their destination.

Tuesday, March 13, 2007

Free stuff from MIT!

http://ocw.mit.edu/index.html

Well, they've been doing this for a while now, but the Massachusetts Institute of Technology has committed to putting pretty much ALL of their undergraduate and graduate courses' teaching material online, accessible to anyone for free!

Well, it's actually not quite as great as it first sounds, because while the teaching material are available, the teachers are not. So you have lecture slides, but no actual lectures. Some of the courses have pretty comprehensive resources, while some others don't.

But still, it's good stuff.

Monday, December 18, 2006

Generic Project Management Methodology

Simon Chun Kwan Chui 19/12/2006

I came across this while researching for my masters thesis. Nothing revolutionary about it, but it succinctly formalises a design-oriented problem-solving system. May be used as a simple checklist or as a skeleton upon which a project may be clearly fleshed out. Not necessarily a linear process.

1. Baseline

Establish a baseline of existing circumstances and processes. This may include mapping operational processes and gathering key performance data on each of those processes, creating quantitative inventories and qualitative descriptions of available resources.

2. Desired state

Establish the desired state for the object or process in question. This may involve evaluations of recognised standards and/or best practices, and may be quantitative and/or qualitative in nature. Wherever possible, establish clear and measurable outcomes that will indicate the achievement of the desired state.

3. Gap analysis

Recognize the gap between where things are and where they are wanted to be. Understand the gap and identify all possible actions to close it, along with the feasibility and resource requirements of each possible action.

4. Concept design

Working from the most promising actions identified, provide a high-level concept view of the desired state or a future state vision for what the successful project will look like. Include deliverables for each aspect of the design, defining both quantity and quality of each.

5. Detailed design

Provide a detailed view of the future state. It will describe all those elements that make the future state a reality and detail all the actions required to accomplish this.

6. Implementation plan

Develop an implementation plan and include the time frame, identified deliverables, assigned ownership and responsibility, transition strategy to manage disruptions of existing processes, and sequence of events to make the future state a reality.

7. Execution

Deploy the implementation plan.

Monday, October 09, 2006

The Great Bridge of Queen Street

The full title of the work is: A Dialogue on the Great Bridge of Queen Street and the Purpose of Cities.

It is the presentation for my final year design project for my Bachelor of Architecture degree at the University of Auckland. The title pretty much sums it up.

Sunday, October 01, 2006

Dull Renders? Use Bloom!

Those who are into their computer games and computer graphics will know what Bloom lighting is. For those who don't, check out the Bloom (shader effect) entry at Wikipedia. Basically, you take the rendered image, increase the contrast, blur it, then overlay it onto the original image. The effect is that the bright areas will bleed into the surroundings, which looks like the glare effect one would experience when looking at a very bright object.

For me, I was trying to figure out how to make my presentation renders look more attractive (as you do). It's very easy to do a bit of light blooming in Photoshop, and the results are well worth the effort.

The first image is the render from 3DS Max. Daylight system, Mental Ray, global illumination, final gather. (Look up the words in bold in the relevant program's help files if you're interested).

Next I put it into Photoshop and I adjusted the Brightness/Contrast. If I remember correctly, I increased both by 40, but obviously the number would depend on the image and the effect you're going for.

Then I duplicated the layer (Duplicate Layer), and put a Gaussian Blur filter on it, with a pixel radius of 10. The amount of blur will affect the spread of the light bleeding, and you might want to experiment a bit to find out what looks good to you.

Finally, I set the top (blurred) layer blending mode to "lighten" and the layer opacity to 50, so that only the light will bleed, and only moderately.

I think the result looks pretty good. Easy process. If you're making an animation, you can even record an action and batch all the frames in Photoshop. Not bad, eh?

Saturday, September 23, 2006

CV and Portfolio

CV (PDF, 28KB)

Portfolio (PDF, 4142KB)

My final year project for my Bachelor of Architecture at the University of Auckland:

SCKChui_dialogue_2006.pdf (4271KB)

My Master of Architecture thesis:

sckchui_Thesis_2007_small.pdf (350KB)

Wednesday, August 30, 2006

Wednesday, July 26, 2006

Whoops. AWOL'ed

Hm. One person at univeristy told me that they've been looking through my old website, and that they found it incredibly amusing to see my old Design work. That's nice.

OK, I'll make sure that I put more of my university work up, if only to amuse you. I'll pretend it's a portfolio or something.

But not right now. Computer games.

Thursday, June 22, 2006

...

Put a link to Blender.org on the links page. Open source 3D modelling, among other things. I've only just started learning it, so don't ask me how to use it yet. The short movie Elephant's Dream is very impressive. Professional quality by any standard.

Wednesday, June 21, 2006

3ds Max Tutorial 002: Give us a Hand

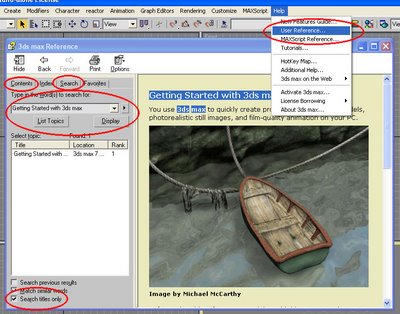

This tutorial describes the making of a material of my left hand, as an introductory overview of the way Discreet 3D Studio Max approaches materials. This tutorial will demonstrate the way different maps may be combined together to make convincing materials, but will not give a detailed, step by step guide for how this is done. 3ds Max comes with a very good online reference, found under Help > User Reference…, and the reader is encouraged to look up certain help topics in the user reference. These topics will be highlighted in bold, and can be searched for in the user reference with the “Search titles only” option checked. Most importantly, the user reference explains all the tools in Max button by button, so this is something that I will not be doing. Instead, I will refer the reader to the user reference.

This tutorial was created with reference to version 7 of 3ds Max, but it should apply to most other versions as well. As a note, it to me 45 minutes to create this hand material from scratch, using Adobe Photoshop and 3d Studio Max.

Know Your Tools

If you are new to materials in 3ds Max, then you have a bit of reading to do. First, go and look up “Material Editor, Materials, and Mapping” in the user reference. After that, follow the link to Designing Materials, which gives an outline of the workflow involved in making materials in Max. It probably goes into more depth then you need to start with, so just read it and don’t worry if you don’t understand everything. Next, look up Material Editor and familiarise yourself with that window. At this point you can also look up Types of Materials to see what’s on offer, but for this tutorial we’ll only be looking at the Standard Material, so make sure you read up on that. At the bottom of that entry, there are further links to sub-entries, which are useful to read. The most important is the Maps Rollout (Standard Material), and at the bottom of that entry are more links again, this time to the different types of maps. I highly recommend you reading up on all of them, but the ones that are dealt with in this tutorial are Diffuse Colour Mapping, Specular Level Mapping, Glossiness Mapping, and Bump Mapping.

Once you’ve read all that, you’ll know more than what you need to know to start making materials in Max. In fact, it may be a good idea for you to try out some of the tools you’ve just read about. But if you keep reading, I’ll tell you about how I make a material of my left hand.

Learning to Look

The secret to making realistic materials is learning to look at things closely. If you’re not interested in realistic materials, you’ll still need to understand clearly what you want to make. I chose to make a material of my left hand for this tutorial because most people have at least one hand on hand to look at, and I will ask you to look very closely at yours right now.

Looking at the palm of my hand, the first things I notice are the creases in the skin. Next I notice that the colour of my palm is generally a yellowish pink, although the tone is not uniform. I can also see faint blue-green veins beneath the skin. The creases in the skin are generally a darker tone than the surrounding flesh. Next, I see that the surface of the skin is somewhat glossy, and as I move my hand around, I can see the specular reflection of the light highlighting the texture and creases.

Having looked at my hand closely, I can now translate what I see into the different maps I need to make. I know that the diffuse colour component is the non-uniform yellowish pink with the blue-green veins and slightly darker creases. I know that the specular level and glossiness components describe how the specular reflection of the glossy parts of my palm highlights the textures. Lastly, I know that the bump component describes the slight grooves formed by the creases. Knowing these things, I drew some maps in Photoshop.

First, I used the brush tool to draw the diffuse map without the creases of the palm. Then I drew the bump map, again using the brush tool but with a much small brush size. I then adapted the bump map to create the specular map, which is basically the same thing but with lower contrast. I then used this map again and adapted it to make the creases in the diffuse map. Then I adapted the bump map again for the glossiness map, adding noise using the Add Noise filter in Photoshop. Actually, it wasn’t quite as straightforward as that. Originally I didn’t have the creases on the diffuse map and the noise on the glossiness map, but I added them after I tried them out in 3ds Max and found them unsatisfactory. Making materials always involve an element of trial and error, and the ability to know how to fix something that doesn’t look right is a matter of understanding how the tools work.

Show Me Some Skin

Once the maps are made, it is simply a matter of putting them in the right slots in the material editor and adjusting the amounts of each map. Below is a screenshot of the material editor after I’ve set everything up, with the changes from the default settings highlighted and a magnification of the sample slot. Once again, working out the amounts for each map is a matter of trial and error, trying out different values to see what works and what doesn’t.

The following are two views of the material applied to a box. The first view has the camera angled to catch the specular reflection from the light; the second view is angled away from the specular reflection.

Below are each of the four components rendered separately by turning off the others. You’ll notice that the specular level, glossiness, and bump components don’t do very much on their own, and need to be combined to have much affect. It is often better to build up the texture of a material using many subtle effects than to try to use only one map.

Debrief

That ends our brief overview of the Standard Material. As you probably gathered by now, materials in 3ds Max can simulate the appearance of objects in the real world, but otherwise they have very little in common. In reality, all the diffuse, specular, and glossiness components of an object are in fact the result of electromagnetic radiation interacting with a collection of molecules at the atomic level, reflecting off those molecules in varying ways. In Max, that interaction is approximated by calculations, components of which may be turned on and off. Therefore, it is important to not expect materials in Max to behave the way one might expect them to behave in the real world, but rather understand that it is a whole other system with different rules.

As I said earlier, the secret to making realistic materials is learning to look at things closely. If I ask you to describe to be a piece of A4, laser quality paper, and you tell me it’s white, then you’re not looking closely enough. Looking at a piece of A4 paper right now, I can tell you that it’s not entirely uniform white, that it has a certain texture formed by the wood fibres that make up the paper, and that it has a certain specular component. In brief, I would say that it is very faintly splotchy. Do not underestimate such subtleties; the human mind is very good at feeling uncomfortable when something isn’t quite right, even if it can’t determine exactly what’s wrong. People often criticise poor computer renders as being “flat”, “dead”, or “plastic”. This is precisely because the subtleties have been overlooked.

Once you have come to grips with the standard material, you may like to have a look at the Raytrace Material, the Architectural Material, and the Ink ‘n Paint Material. Raytrace and Architectural materials allow more effects, most notably reflections, but are also more computationally intensive at render time. It is generally advisable to use the standard material wherever possible, and only use the more advanced materials when you want specific effects that are not possible with the standard material. The Ink ‘n Paint Material generates cartoon-like effects.

I hope this tutorial has been helpful, and I wish you luck with your materials.

Simon Chun Kwan Chui

21/6/2006

Thursday, June 15, 2006

...

3ds Max Tutorial 001: Cubed

This beginners’ tutorial outlines three ways of making a cube, as an introductory overview of the way Discreet 3D Studio Max approaches 3d modelling. This tutorial will briefly introduce the reader to a number of versatile tools in 3ds Max, but will not describe any of them in any great detail. 3ds Max comes with a very good online reference, found under Help > User Reference…, and the reader is encouraged to look up certain help topics in the user reference. These topics will be highlighted in bold, and can be searched for in the user reference with the “Search titles only” option checked. Information that can be easily found in the user reference will not be covered in this tutorial.

Readers who are entirely new to 3ds Max are encouraged to go to the user reference and read the “Getting Started with 3ds Max” chapter. Because of the amount of reading involved, this tutorial may actually take a very long time to complete. However, readers are free to stop after modelling the first or the second cube, as each cube represents a particular approach to modelling which may be sufficient for the reader on its own.

This tutorial was created with reference to version 7 of 3ds Max, but it should apply to most other versions as well.

Box Primitive

To start with, create a Box Primitive, which is a Standard Primitive (if you can’t work out how to do things, remember to look up the words in bold in the user reference). Do not worry about the Creation Parameters for the box at the moment, although it might be a good idea to look up how Parametric modelling works.

Once you’ve created the box, select it using Select Object, and go to the Modify Panel. Under “Parameters”, give the box the same measurements for “Length”, “Width”, and “Height” (I made mine 500mm). Now we have our first cube.

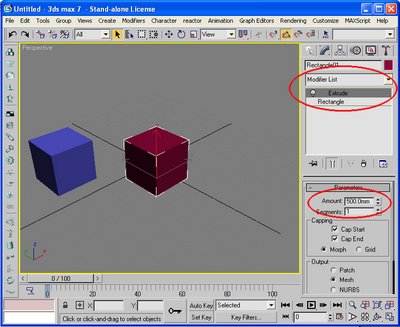

Spline-Extrude

Next, use the Viewport Controls to find some more space if necessary, and make a Rectangle Spline (and maybe find out what Shapes and Splines are, too, while you’re at it). Go to the Modify Panel and make the “Length” and “Width” of the rectangle the same as your cube. Using the Modify Panel, add the Extrude Modifier from the modifier list to the rectangle (at some point, you may want to familiarise yourself with the full List of Available Modifiers). Under the “Amount” parameter, enter the height of the extrusion, which would be the same as the length and the width of the rectangle since we are making a cube. Now we have a second cube.

Spline-Surface

The next part gets substantially more complex, but the tools introduced are also substantially more versatile and powerful. It is highly recommended that you read the user reference entries highlighted, as well as entries on related topics. Remember that you may also un-check “Search titles only” to conduct a general search of the user reference on any topic.

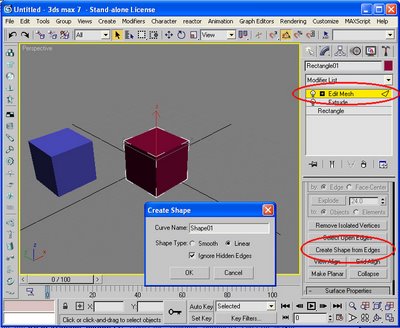

With the second cube still selected, add an Edit Mesh Modifier (also look up its cousin, the Editable Mesh Surface). Using the edge tools (Editable Mesh (Edge)), select all the edges of the cube and click “Create Shape from Edges”, select “Linear” under “Shape Type”, and click “Ok” on the dialogue box that comes up.

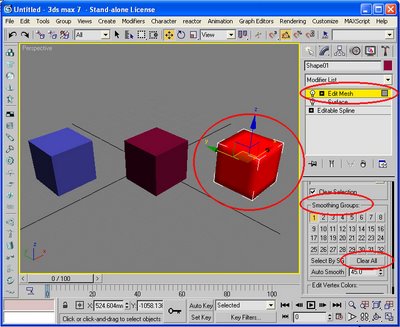

Now exit the edge tools and select the new shape. The new shape is overlapping cube two, so it may be easiest to use select by name. Select and Move the shape away from the second cube. In the Modify Panel, you will see that the shape is an Editable Spline. From the modifier list, add a Surface Modifier. You will now see what appears to be a cube with rounded edges. Add an Edit Mesh Modifier, go into the polygon tools (Editable Mesh (Face/Polygon/Element)), select all the polygons of your third cube, and under Smoothing Groups, click “Clear All”. Exit the polygon tools, and you’ll have your third cube.

Debrief

If you are new to 3ds Max and you managed to complete this tutorial with three cubes and an understanding of how you created them, then you deserve to be congratulated. Although I intended for this to be a beginner’s tutorial, I also knew that the learning curve was very steep, and that a lot of concepts were being covered very quickly. I will now go back and make some comments on what has been covered.

The first cube was the simplest, made using Geometric Primitives. Using only primitives, it is fairly easy and straightforward to sketch a model. Multiple primitives may be arranged and overlapped to increasingly complex compositions, which can be made to resemble just about anything. However, this type of modelling can quickly run into inefficiencies. For example, with complex arrangements of several dozen or several hundred overlapping primitives, it may become extremely difficult to keep track of the way the primitives relate to each other in order to change or adjust the model. Texturing and animation is difficult for the same reasons, and rendering is made inefficient by the large number of redundant polygons that are hidden by other geometry, but nevertheless has to be calculated by the renderer.

The second cube was made using the spine-extrude method, a method that is particularly useful for modelling architectural elements because of the rectilinearity of conventional architecture. Holes can be cut into slabs can be produced by nesting one closed spline within another, avoiding the use of the often unreliable Boolean Compound Object. It is also relatively easy to import plans from CAD programs like AutoCAD and extrude the lines to make a model of a building, as long as the CAD drawings are tidy and drawn with modelling in mind. The obvious limitation of this method is that it is limited to extrusions, and anything that isn’t meant to be a straight extrusion will require additional editing. The extrude is somewhat related to the Lathe Modifier and the Loft Compound Object.

The third cube introduced Surface Modelling with Editable Spline and Editable Mesh, tools that allow full control of every aspect of the model, but which also assumes full understanding of how geometry in 3ds Max works. Basically, a vertex is a defined point in space, an edge is a line between two vertices, and a face is a triangle with a vertex at each corner and joined by edges. An edge has a direction, as in from vertex 0 to vertex 1. A face also has a direction, or a Normal, meaning each face is one-sided (unlike, say, something like a piece of paper, which has two sides). The editable spline and editable mesh, along with the related Editable Patch and Editable Poly, allow the direct creation, manipulation, and deletion of vertices, edges, and faces. These are powerful tools, but they will lead to unexpected results if you do not understand how they work. It is highly recommended that you familiarise yourself with all aspects of the editable spline and editable mesh tools.

The third cube also introduces the spline-surface method of modelling, which is probably best explained by the Surface Modifier entry in the user reference. It should be noted that this method is usually used for organic, free-form modelling, and that the modelling of a cube is not usually done this way. However as shown with the cube, it is not difficult to make inorganic, rigid shapes with this method also. This method of modelling is useful for any complex shape. The most common problem the surface modifier is that it only creates surfaces where the interconnected splines form three or four sided polygons. If you find your model has missing faces after applying the surface modifier, the problem is usually that you have inadvertently created a five or more sided polygon, or that the splines are not properly connected.

I hope this tutorial has been helpful, and I wish you luck with your modelling.

Simon Chun Kwan Chui

15/6/2006

Saturday, June 03, 2006

...

I had originally planned to have a much bigger "Academic" section in my CV where I would describe all the stuff I've been doing at university, but I realised that it would turn by CV into a small book, and that it would take me quite a while to put together. I guess that means I'll put a "portfolio" section on my blog, and put all my work there instead. Host the PDFs on the Orcon account.

Good plan.

Curricula Vitae

Name: Simon Chun Kwan Chui

Email: sckchui@ihug.co.nz

Personal Website: http://sckchui.blogspot.com

I am currently in the final year of my professional Bachelor of Architecture degree at the University of Auckland, and I am looking for employment for when I finish my degree. In my architectural education I have spent much time considering the ethics of architecture and the politics of architecture, exploring these subjects through the design of low-cost social housing, a prison facility, a clandestine underwater nuclear reactor (satirical proposal), and others. For my final architecture school design project, I would like to explore the relationship between architecture and all other human endeavours, to identify and, perhaps, to redefine the scope and purpose of architecture in our unending quest to survive and to thrive.

Employment History:

2006-Current

Architectural Computing Teaching Assistant.

School of Architecture and Planning, University of Auckland

In this role, I am mostly involved in informal tutorials with students, teaching practical computing skills and techniques, as well as discussing general concepts and strategies for using the computer effectively. Software covered in the teaching include Macromedia Flash, Adobe Audition, Adobe After Effects, Adobe Illustrator, Adobe Photoshop, Autodesk AutoCAD, Autodesk 3D Studio Max, Softimage XSI, Microsoft Office, and others.

2005-Current

Academic Mentor

The Schools Partnership Office, University of Auckland

In this role I help two University scholarship winners in the architecture school maintain a Grade Point Average of 6 or above, which is the condition they must meet in order to continue receiving their scholarship. To this end, I give them general advice on all aspects of their studies, including such things as clarifying their learning objectives and demonstrating techniques for producing high quality work.

2005

Computer Aided Studio Helpdesk

School of Architecture, University of Auckland

The CAS Helpdesk role provides general troubleshooting and advice on the software provided in the Architecture Studios in the School of Architecture. The software includes a range of commercial architectural draughting, 3D modelling, image manipulation, video editing, and presentation packages.

2005

IT Helpdesk

National Institute of Creative Arts and Industries IT, University of Auckland

The IT Helpdesk role provides general troubleshooting for the faculty computer labs, as well as minor routine maintenance on the lab printers.

2004-2005

CAD Operator

Aluminium Systems New Zealand Limited

In this role I was responsible for updating an Export Sales Catalogue of aluminium window and door joinery. The manual was compiled almost entirely in Autodesk AutoCAD, and the work involved reformatting all the pages, as well as drawing installation details for new products and updating some old ones. Especially important was the addition of installation details for concrete buildings to supplement the details for timber framed buildings from the old manual.

2004-2005

Digital Visualisation

Science Intermedia Network Environment (SINE), University of Auckland

Working on the Embodied Time(-) Project with Julainne Sumich, Bruce MacDonald, Kevin Novins, Hsu Han Chiang, Jamie Kydd and James van As, I was tasked with visualising some conceptual processes, as a precursor to the development of a computer simulated environment. This involved 3D modelling and presentation work, using Discreet 3D Studio Max, Adobe After Effects, and Adobe Photoshop.

2002-2003

Architectural Draughting

Heslop Design

Working under the supervision of Bruce Heslop, I was mainly given the task of preparing architectural drawings for various residential projects using VectorWorks. I also assisted with site measurement, and I designed and built the Helsop Design website.

Current Professional Memberships:

New Zealand Institute of Architects: Student member

Academic History:

2005-2006

Bachelor of Architecture (active in programme)

University of Auckland

2002-2004

Bachelor of Architectural Studies

University of Auckland

2001

New Zealand University Bursary: A Bursary, with a Scholarship in English

Pakuranga College, Auckland

Other Interests:

Modos: 06 Collection:

Modos is a yearly publication organised by the final year architecture students at the University of Auckland to showcase our work to the public. This year, 2006, being my final year, I am working with a group of my peers to organise this year’s publication.

WAYD:

WAYD stands for What Are You Doing, and is a periodical created by the architecture students at the University of Auckland as an internal forum for the presentation and discussion of student work. I was involved in the initial conception and the first few issues of the periodical, but I have given the work over to students in the lower years who will continue the work after I leave the school.

Habitat for Humanity Auckland University Chapter:

Another student initiative at the School of Architecture, I assist when the opportunity arises.